A suitable checklist could contain the following points:

✅ Legal basis: What do current regulations and standards, such as EPC’s, stipulate for my building? Which measures can or must I comply with at this time?

✅ Environmental compatibility: CO₂ and NOx emissions are the decisive criteria in the environmental assessment of a heating system. Since the CO₂ tax currently determines the cost of fuels and there is a declared goal to eventually phase out fossil fuels, it makes sense to rethink the old heating system. If you look for appliances with low NOx emissions, you get important bonus points for building certification. Ask yourself critically what the idea of ecology is worth to you and whether you want to afford it in this form economically.

✅ Economic efficiency/energy consumption: The energy demand has a significant influence on the operating costs of a company. The efficiency of a heating system influences energy consumption in direct proportion. The dilemma in the assessment: There are no generally valid assessment approaches for the different heating systems. An example: for central heating boiler systems, an efficiency of 108% sounds much better than for decentralised warm air heaters, with an efficiency of 77%. The efficiency of heat pumps is presented quite differently again. That is why it is important to use one’s own expertise and to trust the expertise of professionals. Decentralised warm air heaters, for example, can have significantly better operating costs than a boiler system. For many heating systems, it is best to compare the ErP values from the Ecodesign Directive; for heat pump systems, the value of the seasonal space heating efficiency (ƞs,h-value) is recommended. All manufacturers are obliged to disclose the values.

✅ Building characteristics and building utilisation: The building and its utilisation profile have a significant influence on the heating system. Is it a warehouse with individual workplaces? Is zone heating or full heating desired? How is the building insulated? How high is the building? Are you planning an existing heating renovation or a new building? How long do you plan to use the building?

✅ Heat recovery: Ask yourself to what extent there are possibilities to include process heat in the heating circuit or whether the exhaust gas heat of the heating system can still be used.

✅ Energy sources: To answer this question, one should use one’s green conscience on the one hand and one’s own expertise on the other. While renewable energies always seem clean, fossil fuels struggle with a “dirty image”. But the truth lies in between. While electricity is rated “green”, in fact a not inconsiderable proportion of lignite and natural gas power or imported nuclear power is added to the electricity mix. Solar farms can supply electricity when the sun is shining, wind turbines when the wind is blowing, but unfortunately the storage of electricity during the times when the wind is blowing and the sun is shining has so far been uneconomical. So there is no way around fossil fuels when it comes to feeding electricity into the grid. Ask yourself what makes more sense for you: to use fossil energy in a power plant to produce electricity and transport it over many miles, including the losses, to the households, or is it better to use the fossil fuel directly on site and without large losses? A question of one’s own philosophy.

✅ Technology: Devices available on the market sometimes differ significantly. In the case of heat pumps, it is primarily the seasonal space heating efficiency (ƞs,h-value) that should be taken into account, and in the case of infrared heaters or warm air heaters, the appliance efficiency (ErP values from the Ecodesign Directive), which is derived from the individual appliance components. The evaluation should also include the control system, the maintenance-friendly design and the possibility of using renewable energies.

✅ Quality: Here, the well-known principle applies: “If you buy cheap, you buy twice”. A higher initial investment can pay for itself within a very short time. Pay attention to the service network offered by the manufacturer as well as its guarantee promise and spare parts security. Experience and competence are already evident in the preparation of the planning or heating load calculation. Take advantage of the opportunity to view references.

What are the advantages and disadvantages of centralised and decentralised industrial heating systems?

Industrial heating systems can be divided into centralised and decentralised systems. Central systems almost always have a separate boiler room where, for example, gas, oil, pellets/wood chips or district heating is converted into heat. They usually work in pump-hot water mode. The heated water is then pumped through pipes into the room to be heated. Decentralised systems, on the other hand, convert electricity or the primary energy gas or oil directly into heat in the space to be heated; this eliminates the need for heat transport via pipes.

Advantages of central systems:

- Use of renewable energies possible

- Different fuel use possible, also combinable (fossil and biogenic)

Disadvantages of central systems:

- Heat losses due to long pipelines and spatial separation

- Leakage risk

- Water-guided system must remain frost-free

- Increased demand for electrical drive energy

- Inertia in heating and cooling processes

- Limited flexibility when changing room temperature

- Zone or workplace heating can only be implemented to a limited extent

- Higher risk of failure as there is only one heat source

Advantages of decentralised systems:

- Use of renewable energy possible

- Use of free environmental heat (heat pumps) possible

- Heat available “at the push of a button”, i.e. quickly

- Few transmission losses

- Adapt quickly to temperature fluctuations (e.g. when gates are opened)

- Easy to install

- Also suitable for renovations

- Depending on the solution, very fast amortisation

- Depending on the system, zone and workplace heating is possible

- Do not have to be kept frost-free

- Lower risk of failure due to multiple heat sources (redundancy)

Disadvantages of decentralised systems:

- Not all available systems can use renewable energies

- Increased maintenance effort due to multiple heat sources/burners

In the following, we compare various central and decentralized heating systems that can be considered for big building heating.

Which heating systems are suitable for industrial buildings?

Industrial Heating with Warm Air

Heating systems with warm air use the heat exchanger air to transfer the warmth into the space. Either the existing room air or fresh air supplied from outside can be used. The heat can be generated either directly in the units or at a central point outside the units. A distinction is therefore made between central and decentralised warm air heaters.

Photo: A warm air heater as building heating system in a warehouse.

Heat pump systems:

Heat pumps can be used as a stand-alone heating system or in a hybrid system, e.g. with gas-fired tube heaters.

Basically, a heat pump extracts energy (heat) from the environment and transfers it to the interior of the building. A distinction is made between heat pumps depending on which type of heat delivery system is used and how the heat is introduced into the buildings space. The most commonly used heat pumps for industry are air/air and air/water heat pumps (energy source/heat output). Modern heat pumps can now extract enough heat from the environment, even at temperatures below freezing, to heat buildings economically.

Advantages:

- Environmentally friendly, especially when using self-generated or green electricity

- Low operating costs, use of free environmental heat

- Various distribution systems possible in the room (textile hose, jet nozzles, central outlet heads, etc.)

- Can be combined with other heating solutions as an economical hybrid solution

- Flexible and compact

- Cooling mode possible

Disadvantages:

- Restrictions in case of renovation

- High investment costs

- No zone heating possible

- Dust turbulence and draughts possible

- Physically conditioned air stratification

Photo: Outdoor units of a heat pump system on a building´s roof

Decentralised, gas-fired warm air heaters

The heat is generated by means of burners directly in the individual units in the room to be heated and blown into the space. The burner can work with room air or fresh air.

Advantages:

- No losses of the heat by transfer from the heat generation to the part of the building to be heated

- No risk of water leakage

- System is frost-proof

- Relatively short heat up times

- Low risk of failure due to multiple burner units

- Possibility to supply fresh air to the room

- Simple installation

- Low investment costs

Disadvantages:

- Limited use of renewable energies possible (only biogas)

- Noise generation

- Dust whirling up and draughts possible

- Physically conditioned air stratification

- High operating costs

Central warm air units (air heaters)

The heat is generated centrally, usually outside the room to be heated. Possible options would be, for example, a condensing boiler, a pellet heating system or the provision of heat via district heating. The hot water generated is routed via pipelines to the individual warm air units or blow-out points distributed in the building and from there blown into the building as warm air via a heat exchanger.

Advantages:

- Low-cost individual units

- Easy-to-maintain discharge points

- Use of renewable energies possible

- Usually easily accessible burner unit

Disadvantages:

- System must remain frost-free

- Long pipelines to the individual units lead to system-related heat losses

- Risk of leakage

- Longer heat up times necessary (inertia)

- Higher risk of failure as there is only one heat source

- Noise generation

- Dust whirling up and draughts possible

- Physically induced air stratification in the room

Heating systems with infrared heaters

Heat does not necessarily have to be brought into the building via warm air. Heat transfer through infrared rays should always be considered when looking for an industrial heating system because of its many advantages. Infrared systems are among the most economical industrial heating systems available. They score points with a fast “return on investment” and are ideal for heating system renovations.

The principle is simple and is often explained with sunbathing on a glacier. Although the ambient temperature is in the minus range, it is warm in the sun. This is due to the heat radiation or infrared radiation of the sun. Where the infrared rays hit our skin, they are converted into heat.

Infrared devices do not need a carrier medium to transfer the heat energy. It passes from the device to the object almost without loss and does not cause any draughts. Because infrared radiators primarily heat surfaces, the air temperature can be on average 2-3 °C below the temperature felt by humans but is still perceived as comfortable. These factors have a positive effect on the indoor climate and the economic efficiency of the systems. Depending on the system and the application, up to 50 % energy can be saved compared to conventional heating systems.

Photo: A tube heater under the roof of an industrial building.

Plaque heater systems

Luminous (plaque) heaters are operated directly with natural gas, liquid gas or biogas. Installed on walls or ceilings, they are mainly used to heat high buildings, individual workplaces or outdoor areas and stadiums. They are called luminous heaters because the combustion of the gas-air mixture is visible through glowing ceramic plates. The ceramic plates reach a surface temperature of 950 °C and therefore emit particularly high levels of infrared radiation. Reflectors direct the radiation specifically downwards into the occupied area of employees. Modern units are modulating and can be ideally adapted to the actual heat requirement of the building. Optionally, the units can be equipped with a condensing module to utilise residual heat from the exhaust gas and to work even more energy-efficiently.

Advantages:

- Particularly effective and energy-saving thanks to high infrared radiation component

- Low-NOx burner technology

- Highly economical, as no air needs to be heated up

- No expensive heat layers under the building roof

- Additional energy saving as the room temperature can be regulated lower with the same level of comfort

- Fast response times – warm at the push of a button, so to speak

- No dust or air turbulence

- Heating of zones or individual workplaces possible

- No freezing

- Simple installation

- No flue gas ducting

- No annual chimney sweep measurement

- Fail-safe due to several burner units

- Outdoor heating possible

Disadvantages:

- Can only be used for building heights over 4 metres

- Limited use of renewable energies (only biogas)

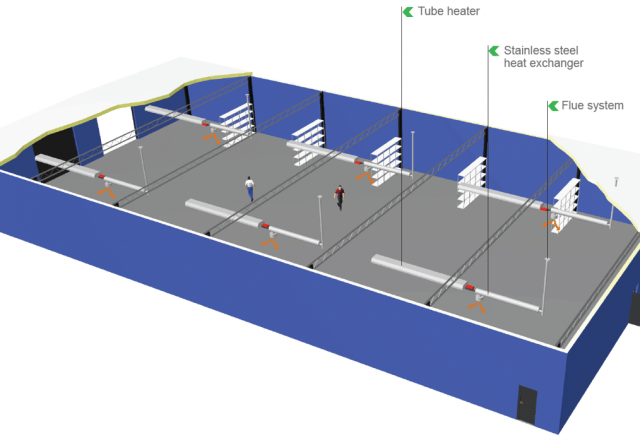

Tube heater systems

Tube heaters generate heat by burning a gas-air mixture or, ideally, by burning 100% hydrogen in closed radiant tubes. The combustion is not visible, hence the name “tube” heater. The hot gases produced heat up the surface of the radiant tubes, which then emit the heat in form of radiation.

The radiant tube is covered by a reflector that directs the heat radiation into the desired area. Tube heaters discharge their exhaust gases directly from the building. Modern units work with a gas-air compound and can adjust their output continuously to the actual heat requirement. This saves energy and improves the indoor climate.

Tube heaters can be used in rooms with ceiling heights as low as about 4 m. They can be used in workshops, industrial rooms, warehouses, etc. Whether workshop, industrial, storage, exhibition or sports buildings – tube heaters can be used for almost any application.

100% hydrogen units can be used in stand-alone solutions in which industrial building operators convert their own electricity produced in summer into hydrogen and store it. In a few applications in Germany, the H2 tube heaters are directly connected to small hydrogen networks.

Advantages:

- Depending on the manufacturer, 100% hydrogen-compatible

- Particularly effective and energy-saving thanks to high proportion of infrared radiation

- Hybrid-compatible with heat pump systems

- Low-NOx burner technology

- Highly economical as no air is heated

- No expensive hot air cushions under the hall roof

- Additional energy savings as the room temperature can be controlled lower while maintaining the same level of comfort

- Fast reaction times

- No dust or air turbulence

- Zone or individual workstation heating possible

- No freezing

- Fail-safe due to multiple burner units

Disadvantages:

- Exhaust gas routing necessary

- No use of renewable energy possible with conventional appliances

- Currently only one manufacturer can use 100% hydrogen

Electric infrared heaters:

Electric infrared heaters convert electrical energy into infrared radiation. They use the same principle as the gas-fired radiant heaters.

Advantages:

- Short heat-up times

- Targeted heat emission

- No dust swirls or drafts

- Possibility to set up heating zones

- Low thermal heat loss

- Low maintenance

- Uniform and comfortable heat

- Can be used as part of a hybrid solution.

Disadvantages:

- Higher consumption costs than gas-fired radiant heaters

- Lower installation heights than gas-fired radiant heaters

Central radiant ceiling panels

Ceiling radiant panels belong to the infrared heaters but are supplied with hot water centrally. Installed on the ceiling, they also transmit their heat by emitting electromagnetic waves (infrared rays). Ceiling radiant panels also called hot water ceiling radiant panels are fed with hot water coming through pipes from a central boiler, air-to-water heat pump or brine-to-water heat pump. As with other central systems, radiant ceiling panels are subject to inertia and have limited ability to respond to rapid temperature changes.

Advantages:

- Can also be used for low buildings

- No dust swirling up

- Low air stratification and warm air cushion under the building’s roof

- Use of renewable energies possible

Disadvantages:

- Only limited workstation or zone heating possible

- Long lead times necessary (inertia)

- Long pipelines to the individual units lead to system-related losses

- Risk of leakage

- System must remain frost-free

- Inflexible in case of rapid temperature changes in the building

- Higher risk of failure because of only one heat source

- Design-related risk of shading of lights and sprinklers

- Very high weight, roof statics must be checked

Industrial heating via underfloor heating

Central underfloor heating

The function of underfloor heating for industrial buildings is no different from the one we know from the residential sector. Here, hot water is routed through composite pipes embedded in the floor, thus heating the floor evenly. The hot water is produced by a central boiler, an air/water heat pump or a brine/water heat pump.

Photo: Large-area underfloor heating as a heating system in a new-build building.

Advantages:

- Uniform heat distribution over the entire building area

- Also suitable for low heights

- No dust whirling up

- Low air stratification and warm air cushion under the building’s roof

- Use of renewable energies possible

Disadvantages:

- High purchase or installation costs

- No zone heating possible

- Inflexible in case of change of use of the building (e.g. foundations for machines)

- Very sluggish system

- Temperature changes can only be controlled with a lot of flow

- Susceptible to frost

- Floor load ability limited or only cost-intensive to realise

- Risk of failure as only one burner unit

What is the most efficient heating system for industrial buildings?

Conclusion: Each industrial heating system has its advantages and disadvantages.

In the case of renovations, the operator can still fall back on almost all systems. Those who want to support the idea of ecology in the best possible way sometimes have to dig deep into their pockets for the purchase and ongoing operating costs. Those looking for an ecological and at the same time economical system should consider the possibility of combining several types of heating and controlling them intelligently.

In summary, however, it can be stated that centralised systems can compensate for their transformer losses and lower annual utilisation rates through the use of renewable energies – decentralised infrared heating systems score points through rapid amortisation, high annual utilisation rates and flexible operation, heat pump systems through the use of renewable energies.