An early post on Schwank’s ErP Compliance blog observed that “One example of EU legislation that achieves almost universal acceptance in principle is the Energy-related Products (ErP) Directive (formerly titled Ecodesign Directive 2009/125/EG). This is probably best known by the public for having instigated a ban on the 60W light bulb throughout EU member states.”

These far-reaching regulations have sought to minimise energy usage in both how products operate and how they are produced, including those supplied by the HVAC sector. These objectives are also complemented by solutions that recover energy which would otherwise be lost.

For instance, heat that would normally be wasted can be recovered from factories, incinerators and other commercial buildings. In a press release issued in December last year, the UK government confirmed its commitment to heat networks, also known as district heating.

This announced that over £19 million of government funding would go towards setting up five new heat networks located in Bristol, Liverpool, London and Worthing.

The government explains that: “The £19.1 million funding announced today comes from the government’s £320 million Heat Networks Investment Project (HNIP), which supports the development of heat networks across England and Wales.”

“Government-funded heat networks currently being developed include Leeds City County’s 16km district heat network, Cardiff Town Heat Network in South Wales, spreading across the Cardiff Bay area, and Newcastle University’s District Heat Network within their city centre campus.”

The technology of heat recovery

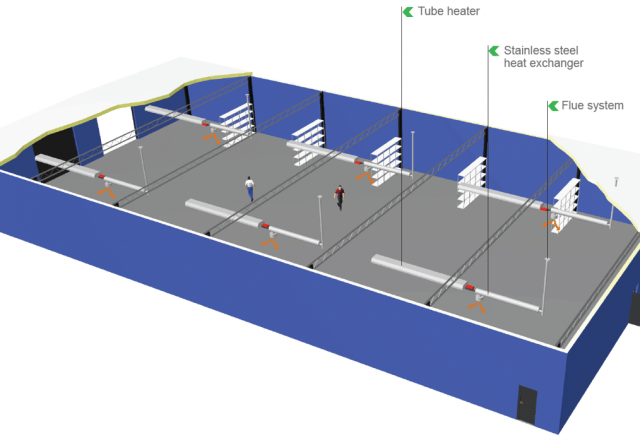

The principle of heat recovery used in district heating networks can also be applied effectively in individual industrial and commercial buildings. In our website information on Condensing Technology, we explain that: “The hybrid solution by Schwank creates a most efficient heating system through the symbiosis of: ecologically-operated gas infrared energy-efficient space heaters and innovative energy recovery systems. All heat recovery systems are individually adapted to the requirements on site and designed according to the residual heat produced.”

hybridSchwank hydro

The range of Schwank’s heat recovery installations has included a project for Bauer in Germany. By using the hybridSchwank solution:

- Heat is recovered from the exhaust gases of Schwank’s energy-efficient infrared tube heating system installed at Bauer and fed into an air-water heat exchanger.

- This exchanger then gives out the heat energy of the exhaust gases in the form of hot water, which is directed into a hot water storage cylinder.

- This supports the hot-water heating of Bauer’s offices, both saving energy and reducing carbon emissions.

The study explains that: “By combining heat insulation measures and the installation of Schwank tube heaters, Bauer was able to save 650,000 kWh in the facilities per year. The comfort, especially at the frequently open workshop doors, has increased noticeably.

“In addition to this, the heat recovery saves another 55,000 kWh [max.] in the office premises per year. This results in savings of 51% for the production facility areas and of 29% for the offices during a statistical standard winter.”

Energy efficiency is a top priority

The opening paragraphs of the EU Energy Efficiency Directive (subsequently superseded by the ErP Directive) emphasise the priority that is given to energy efficiency in the EU’s environmental strategy. To quote: “One of the initiatives of the Europe 2020 Strategy is the flagship resource-efficient Europe adopted by the Commission on 26 January 2011. This identifies energy efficiency as a major element in ensuring the sustainability of the use of energy resources.”

At the historic COP26 meeting in Glasgow last year, there were signs of progress. A post by EDIE environmental news channel reported that:

“The UK Government and the International Energy Agency (IEA) launched a COP26 Product Efficiency Call to Action, which aims to double the energy efficiency of air conditioning, refrigeration, industrial motor systems and lighting by 2030. These four activities account for more than 40% of global electricity demand every year.

“In total, 14 countries have now signed onto the initiative, which is the largest of its kind.”

COP26 took place in spite of a global pandemic, but the subsequent tragic conflict in Ukraine has driven a wedge through international cooperative projects. Apart from the appalling level of fatalities and injuries it has inflicted, energy costs have spiralled and inflation has reached levels not seen in decades.

Objectives that remain unchanged

However, these turbulent times have also emphasised that energy provided for industry and public utilities need to be focused on areas that should also assist in reducing carbon emissions, namely:

- Energy security through decreased dependence on unreliable or potentially politically hostile supply sources via renewables and other solutions

- Energy efficiency through technological advances and focused reduction strategies

- Energy diversity to offer flexibility in sourcing supply

- Energy recovery to eliminate wastage, reduce costs and contribute positively to net zero targets

Schwank is continually active in providing solutions for industry and commerce that will use energy efficiently, cut operating costs and reduce carbon emissions.

Schwank product range

We have recently developed tube heaters that will be able to run on 100% hydrogen power and have introduced a range of Solar Air Collectors offering free heat without the need for conversion to electricity. Our heating solutions have also been capable of running on biogas for some considerable time.

Systems for heat recovery also play an important role in our range of options to meet today’s energy objectives. Having a variety of technological solutions to offer customers means that the differing individual demands of each business can be accurately and effectively met.

No matter what the scale or complexity of an HVAC installation might be, Schwank engineers have the experience, skills and resources to ensure that it is carried out to the very highest standards. Eliminating energy wastage and promoting energy efficiency are goals that drive us in every project we undertake.