Electric Radiant Heaters: The Solution for Workshops

As the world grapples with the pressing challenges of climate change and environmental degradation, industries are increasingly being urged to adopt sustainable practices. One sector that demands attention is the energy consumption of workshops, particularly concerning heating systems. Traditional energy sources contribute significantly to greenhouse gas emissions, making it imperative for these facilities to transition towards greener alternatives.

Current Challenges

Workshops are notorious energy consumers, with their enclosed spaces requiring substantial amounts of energy for heating purposes. Conventional heating systems often rely on fossil fuels, contributing to air pollution and escalating carbon footprints. The need for immense energy to regulate workshop temperatures not only strains local power grids but also places an unsustainable burden on the planet.

The Environmental Impact

The environmental consequences of continuing with conventional energy sources in workshops are well known. Greenhouse gas emissions, a by-product of burning fossil fuels, contribute significantly to climate change. By transitioning to greener alternatives, such as electric heating systems, workshops can play a pivotal role in mitigating these adverse effects and fostering a more sustainable future.

Renewable Energy Solutions

The shift towards greener energy resources for heating in workshops holds immense potential for positive change. Here are some options:

- Electric Heat Pumps: Electric heat pumps use environmental heat, making them an energy-efficient and sustainable heating solution. They can significantly reduce energy consumption and greenhouse gas emissions. Heat pumps transfer heat from the outside air, ground, or water into the workshop, providing consistent and efficient heating.

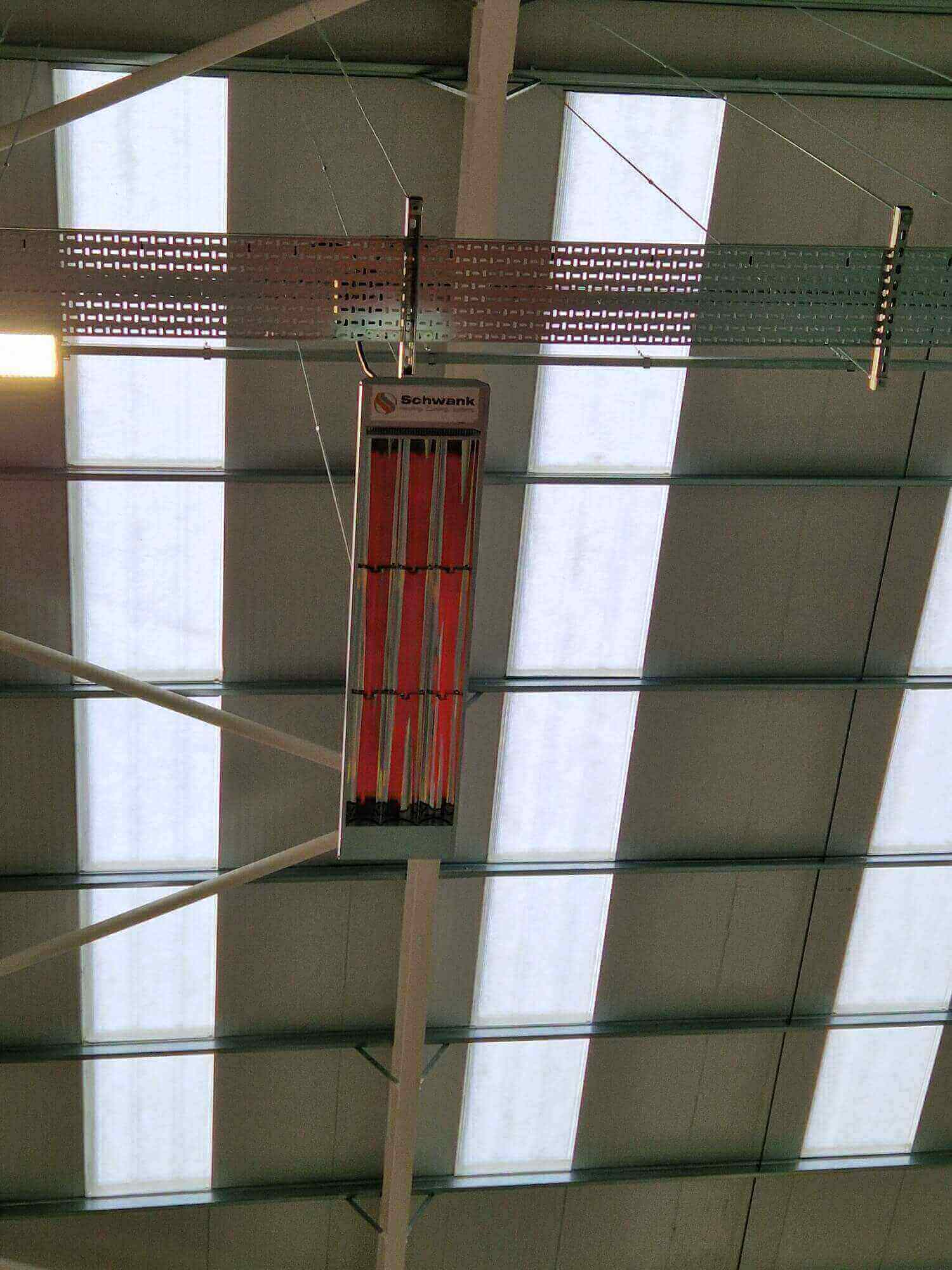

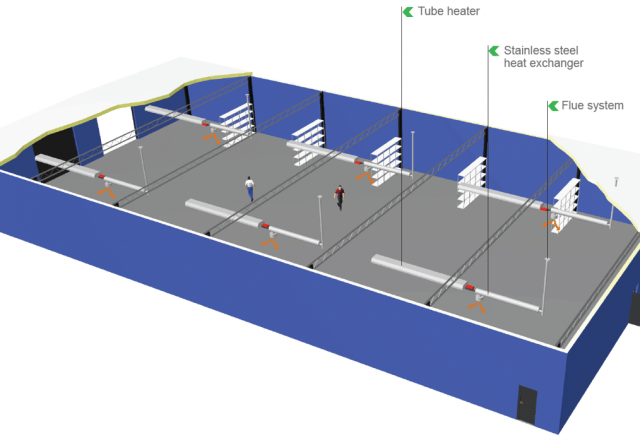

- Electric Infrared Heaters: Electric infrared heaters produce instant heat and are a popular choice for workshops. They provide comfortable and cost-effective heating by directly warming objects and people rather than the air. This method of heating is highly efficient, reducing overall energy consumption and minimising environmental impact.

But what are the pros and cons of moving to electric heating for workshops?

Pros

Environmental Benefits:

- Reduction in Greenhouse Gas Emissions: Electric heating systems, particularly when powered by renewable energy sources, significantly reduce greenhouse gas emissions compared to fossil fuel-based systems.

- Lower Air Pollution: Electric heaters do not produce the harmful pollutants associated with burning fossil fuels, leading to improved air quality.

Energy Efficiency:

- High Efficiency: Electric heat pumps and infrared heaters are highly efficient, converting a large proportion of energy into heat. Heat pumps, in particular, can achieve efficiencies greater than 100% because they transfer heat rather than generate it.

- Targeted Heating: Infrared heaters provide targeted heating by directly warming objects and people, reducing wasted energy on heating the air.

Cost Savings:

- Lower Operating Costs: Over time, electric heating systems can be more cost-effective due to their high efficiency and the potential for lower energy costs, especially when paired with renewable energy sources.

- Government Incentives: Many governments offer incentives, tax breaks, and grants for businesses adopting renewable energy and energy-efficient technologies.

Cons

Initial Investment:

- High Upfront Costs: The initial investment in electric heating infrastructure, including the cost of heat pumps or infrared heaters, can be substantial. This may be a barrier for some businesses, particularly small workshops with limited budgets.

Dependence on Electricity:

- Grid Reliability: Workshops relying solely on electric heating are dependent on the reliability of the local electricity grid. Power outages or grid issues can disrupt heating systems unless backup power solutions are in place.

- Electricity Source: If the local electricity supply is primarily generated from non-renewable sources, the environmental benefits of switching to electric heating may be diminished.

Retrofit Challenges:

- Compatibility: Retrofitting existing workshops with electric heating systems can be challenging and may require significant modifications to the building’s infrastructure.

- Space Requirements: Some electric heating systems, like heat pumps, may require additional space for installation, which could be a constraint in smaller workshops.

What should you do?

While transitioning to electric heating in workshops offers numerous environmental and economic benefits, it also presents challenges, particularly related to initial investment and infrastructure compatibility. By carefully weighing the pros and cons, workshops can make informed decisions that align with their sustainability goals and operational needs. If you are unsure if electric is the best form of heating system for your workshop, and would like to discuss your options, please contact us.

Get personal advice now!