What is the ErP Directive?

The ErP Directive has its origins in the EuP Directive from 2005, but it only referred to energy-using products such as computers or refrigerators. Later, it became the Er Directive, which also included windows or tyres, for example. The idea behind the EU directive was to create a differentiated assessment scheme for different product groups. The environmental relevance of products is made up of materials, energy and water consumption as well as pollutant emissions. For household appliances, energy labelling in classes was created in the course of this. Today, we find the classification of an appliance in A+, A, B, C etc. on the eye-catching colourful stickers. Only appliances for commercial and industrial use are exempt from the labelling obligation via stickers. This is because it is assumed that the purchase of such products is always made through prior consultation or specialised purchasing. Nevertheless, manufacturers must communicate the efficiency values for each product openly and transparently. This uniform labelling obligation creates a transparent comparability of energy consumption. The results of the ErP that must be labelled are therefore energy efficiencies that can be calculated from different parameters and emission limit values. Appliances that do not meet the minimum efficiencies of the ErP Directive may no longer be sold.

What is the evaluation scheme for heating systems?

The individual product groups are summarised in so-called LOTs. LOTs 20 and 21 form the groups of domestic and commercial space heaters. About every three years, the European Commission looks at the developments of the different systems in the LOTs and assesses whether the applicable limit values are still up-to-date. If the Commission comes to the conclusion that, for example, a manufacturer could realise stricter values with its technology, the directive is adapted in the sense of better environmental compatibility, i.e. the limit values are tightened. The focus of the assessment is on energy efficiency and pollutant emissions during operation.

There is a uniform parameter for the energy efficiency industrial heating systems in the ErP Directive of 2018: the annual utilisation factor or also called seasonal energy efficiency. The consideration of partial and full load efficiencies, which is equivalent to the consideration of an average heating season, is also one of the main features of this ErP Directive. The Commission responsible for the Directive has correctly recognised that heating systems operate on average 85% in part-load mode, i.e. in the transitional periods, and only about 15% are required to operate at full load [this ratio also applies, incidentally, to all other heating appliances such as condensing boilers, etc.].

In addition, poor controllability of heaters [e.g. 1-stage] is also “penalised” with a points deduction – such as heaters that require a high auxiliary energy. Efficient electric drives and fans thus become a must.

Thus, seasonal energy efficiency [ƞs[eta]] is composed of:

- the seasonal efficiency ƞs,on

- the thermal efficiency ƞs,th

- the heat transfer efficiency by radiation ƞs,RF

- the efficiency at minimum power ƞmin

- the efficiency at nominal power ƞmax

Defined correction factors such as the electrical auxiliary energy are subtracted from this.

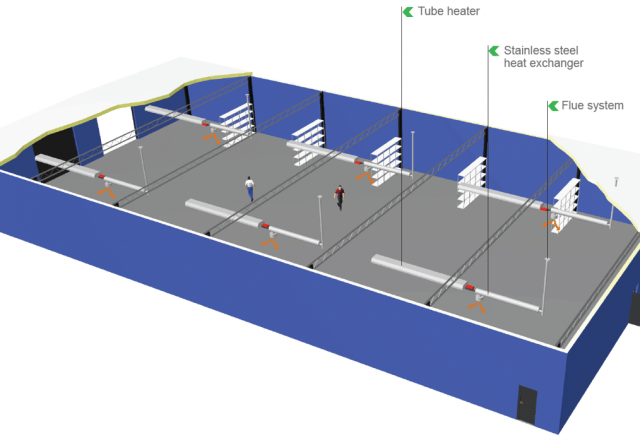

What are the minimum requirements for industrial heating systems?

Industrial heating systems with gas infrared radiators are very energy-efficient compared to other heating systems and emit low levels of CO2 and NOₓ. With modulating control and good radiation factors, infrared radiators can realise values well above the minimum requirements. Fully modulating dark radiators, for example, today achieve seasonal efficiencies of up to 99% and around 60 mg/kWh NOₓ emissions. The minimum requirements for seasonal efficiency are 74% and 200 mg/kWh NOₓ respectively.

For the group of infrared radiant heaters, the minimum efficiency requirement is higher at 85%. But even here, modern, fully modulating units achieve ErP values of up to 98%. infrared radiant heaters also have a technological advantage in combustion and the resulting NOₓ values. The most efficient units produce just 18 mg/kWh NOₓ.

Minimum requirements of the ErP Directive for industrial heaters (infrared radiant heaters and tube heaters):

● NOₓ- Emissions: ≤ 200 mg/kWh (Hs)

● Tube heaters: ηs ≥ 74%

● Infrared radiant heater: ηs ≥ 85%